All about timber beds

Furniture from a bar is characterized by high quality. That is why beds made of this reliable and durable material are very popular today. In this article, we will learn all about the characteristics of these furniture designs.

Peculiarities

Modern furniture made from natural timber has many distinctive features that make it popular.

- The log bed is environmentally friendly and absolutely safe interior item. There are no dangerous and caustic substances in the composition of natural raw materials. The same cannot be said about most modern materials used in furniture production.

- Timber bed fits perfectly into a variety of interiors. Such furniture can easily become a decoration of the situation, its harmonious addition. Lumber beds look attractive in a large number of styles.

- Natural designs often emit subtle natural scentsthat many people like.

- Lumber furniture is reliable and durable... Strong structures are not susceptible to mechanical damage, are designed for long-term operation, therefore they will not require quick replacement.

- Lumber beds are presented in a rich assortment. On sale you can find a lot of first-class models with different dimensions and designs. You can choose the best option for every taste and color.

Before choosing a chic bed from a bar for a bedroom, it is worth learning about some more features that it has.

- In order for such a bed to be organically and comfortably placed in a room, it must have the appropriate dimensions.... Timber beds are noticeably massive, so they are not suitable for small bedrooms. If such furniture is placed in a small room, then it will seem even tighter.

- Furniture structures made from natural timber can be very expensive. Of course, high-quality beds made from natural materials are worth their money and easily work them off, so people rarely regret the money spent.

- It is quite possible to make a very attractive and reliable bed from a bar with your own hands... Such work is often carried out by people who do not have the appropriate experience and skills.

Using the detailed step-by-step instructions, even an inexperienced home craftsman can make reliable furniture.

Types of structures

Timber beds differ in their design features. You can purchase the following types of models in the store or make your own hands.

- Standard... Standard designs are among the most popular. They are found most often, characterized by a familiar device. The height of standard furniture structures is usually between 50 and 60 cm.

- Podium... This option is done quickly, without requiring much effort. A product with a podium structure can be a wonderful decoration for a home, as it is characterized by an original design. Such models are very close to the floor surface, due to which the users feel comfortable and calm.

- High bed. Tall models of beds from a bar look very attractive. Such specimens have a height of up to 80 cm. As a rule, these are structures consisting of several tiers.

Usually they are more expensive, but they are also more functional and practical.

You can choose a worthy and suitable option for a wide variety of layouts and environments.The main thing is to pay attention to the correspondence of the quadrature of the room to the dimensions of the bed.

Dimensions (edit)

High-quality timber beds are made of different sizes. You can buy or order both small and very spacious options. Compact single models are very popular today.... In the lion's share of cases, they are bought for children or adolescents. For users of these age categories, beds often act not only as a place to sleep, but also as a recreation area where you can watch a movie, read your favorite books, and listen to different music.

Single-bed varieties are comfortable and practical. They take up much less free space, so they fit more easily into various environments.

Are in demand and double varieties of beds from a bar... These furniture designs are characterized by spaciousness, ample free space. Double beds made of natural timber attract buyers with their expensive appearance, comfort, and practicality. Such varieties of furniture designs fit well not only in the classical style or country, but also in modern interior compositions, which speaks of their versatility.

When choosing a bed from a bar, it is very important to pay attention to its dimensional parameters. Furniture should harmoniously fit into the environment, and not weigh it down.

Style and design

It seems to many people that such furniture designs are suitable only for the country direction. This opinion is erroneous. Let's find out in what other style directions the timber beds look organically.

- A bed made of timber will look good in a classicist style setting. For such interiors, it is advisable to choose a bed that has clear and restrained shapes, as well as a sufficiently high back.

- Good timber beds look in style provence... Models painted in light and pastel shades are ideal for such interiors. An effective addition will be a bedspread decorated with floral patterns. The effect of craquelure on the furniture body will look interesting.

- Sleeping beds made of timber fit well in a modern interior. For example, a model made in the form of a catwalk will look spectacular in a minimalist bedroom.

- For eclectic interior compositions, it is recommended to select more massive models, complemented by an impressive amount of textile components.

- In the loft style, a sleeping bed made of timber will also look very organic and attractive. It is best to place such furniture in an interior where there is a brick wall, as well as rough ceiling beams.

What is required?

It is quite possible to build a solid and reliable bed from a bar with your own hands. For this, it is imperative to use high-quality materials, as well as properly working tools.

Let's find out what kind of tools you need to assemble a solid bed from a bar with your own hands:

- a circular saw;

- square;

- pencil and tape measure;

- Miter saw;

- hammer;

- sheets of sandpaper;

- drill;

- screwdriver;

- clamps;

- socket wrench.

In addition to tools, the master will need to stock up on high-quality materials from which he will assemble the bed. The following positions will be needed:

- bars with a section of 5x10 or 5x15 cm;

- boards for the side of the bed: the width of the board should be from 30 to 35 cm, and the thickness should be over 2 cm;

- for lamellas, bars with parameters 3x5 cm will be needed;

- fastening components - ordinary metal corners are perfect;

- plywood sheet that will be used to make the headboard;

- glue solution, self-tapping screws, various finishing materials.

A good sleeping bed can be made from a bar with a section of 200x200, 100x100 or 150x150 mm. Each master chooses the ideal material himself. The main thing is that it is in good condition.There should be no signs of decay, defects and damage, traces of mold on wooden parts. It will not be possible to assemble a strong and durable bed from such components.

DIY manufacturing technology

Even an inexperienced home craftsman can independently make a first-class bed from natural timber... If there are no useful skills in such matters, it is advisable to familiarize yourself with the step-by-step instructions for making high-quality wooden furniture.

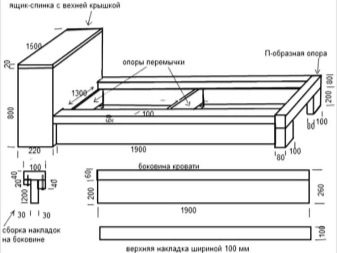

Schemes and drawings

At the initial stage, it is necessary not only to prepare all the necessary tools and materials, but also to draw up a detailed project of future homemade products. The master will need to sketch detailed diagrams and drawings of the bed, indicating absolutely all dimensional parameters. In addition, the sketch should note all the nuances and features of the future design, indicate the connection points of different parts. A detailed drawing will allow you to clearly represent the future product when assembling it.

Some people decide to order a project of such furniture structures from professionals. Of course, this entails additional costs. If you do not want to invest in such processes, then you can draw up a plan for the future wooden bed yourself. In this case, the master should observe the utmost care in order to avoid serious mistakes during the further assembly.

Cutting materials

The next important stage of work is cutting the purchased materials. Let's consider in detail how this should be done according to all the rules.

- First you need to prepare 2 parts for the future bed frame. We are talking about parts with dimensions 25x200x2050 mm. Also, for the frame, you will need another pair of components 25x200x1485 mm.

- For the supporting components of the furniture, you will need 3 blanks 50x100x2020 mm.

- The legs will be 6 structural elements with the following parameters - 100x100x105 mm.

- For the base, only 19 slats are required, which are characterized by such dimensional values - 25x75x1480 mm.

- A bed made of timber will look much more stylish and attractive if supplemented with decorative components. To prepare them, the master will need to cut 2 boards 25x50x1575 mm. Another board 25x50x2020 mm will come in handy.

If a profiled, glued beam or board is used for self-assembly of a high-quality bed, then the master will definitely need to make sure that the spliced sections do not coincide with the sawing lines.

Assembly

When absolutely all the necessary elements have been carefully prepared, the master can safely proceed to assembling the structure of a wooden bed. Consider how at this stage you need to act correctly.

- First, you will need to assemble the frame of the furniture structure. The blanks, from which it is planned to make the frame base and supports, will need to be fastened to each other by means of self-tapping screws and metal corners. Thus, it will turn out to assemble the frame base of the bed. An auxiliary spacer will need to be installed in the middle.

- In the next step, you will need to prepare 4 or 6 legs with the same parameters. They are attached to the lower half of the frame base.

- Support blocks with dimensions of 4x4 cm are attached to the surfaces inside the frame, located on the sides. These components will act as a base on which the lamellas will subsequently be laid.

- The technician should place the support piece for the lamellas in the lower half of the frame base. With this installation technique, the edges of the frame will allow the mattress to be fixed unhindered.

- Then you should start installing the slats... They will need to be laid with a small gap from each other (5 cm is enough). They can be fixed on the support bars by means of self-tapping screws.

- The next step is to connect a pair of bars to the support legs., and it will be possible to attach the future headboard to these bars.

If all the constituent components of the future furniture structure were cut correctly, then the bed assembly process will be simple and hassle-free. You need to act carefully, without unnecessary haste, in order to avoid unnecessary mistakes.

Finishing

When the process of assembling the future wooden bed is completed, the master can devote time to finishing the still "raw" structure. We will find out exactly how it will be possible to qualitatively finish a homemade sleeping bed from a bar.

- To get started, the master will need carefully grind the structure. All wooden surfaces must be perfectly smooth and neat. You need to get rid of any irregularities.

- Further, by means of a putty, it will be necessary to carefully fill absolutely all the available cracks.that were seen in the design. You can choose any color, but a shade close to natural wood will look best.

- When the putty on wooden surfaces is completely dry, the master will need to re-sand all areas., which were previously finished with compositions of suitable colors.

- After that, it is very important to wipe off any wood dust remaining from sanding with the utmost care. from the surface of natural homemade products.

- This is followed by the final stage of finishing work. It consists in applying varnish to the bed. Instead of varnish, it is permissible to apply paints of suitable shades. It is recommended to give preference to high quality fast drying and environmentally friendly formulations.

When the varnish or paint is dry, the mattress can be laid on the finished structure.