How to make a floating bed with your own hands?

A floating bed is a piece of furniture made in a special way.... When you look at it, you get the feeling that the thing is hovering above the ground. They look just magical in the interior. In fact, there is no secret: the design features allow you to achieve this effect. You can assemble such a bed with your own hands if you wish.

We draw up a project

The "flying" bed is an incredibly beautiful accessory. The sleeping area floats in the air, giving the whole room a futuristic and unusual look. It's all about the design of the bed support. The usual legs are absent from such a bed. They are replaced by a base, which is smaller in width and length than the frame.

The hover effect can be enhanced by if you equip the lower surface of the furniture with lighting... Attach the LED strip along the frame and enjoy an additional original night light source. LED strips also allow you to create unique designs with different colors and burning modes.

Fastening such furniture excludes loosening over time, as can happen with ordinary legs. In addition, lifting off the floor makes cleaning much easier. For example, a robot vacuum cleaner can do all the work for you.

First, choose the look you want. Search the internet for photos of the models and draw your own designs based on the images you like.

Do not forget to take into account the dimensions of the future bed. Measure the installation site carefully. Think about what the headboard will be like, whether you need a side at the feet, upholstery or an additional drawer. When the image of the future bed is in your head, it's time to draw up an assembly plan.

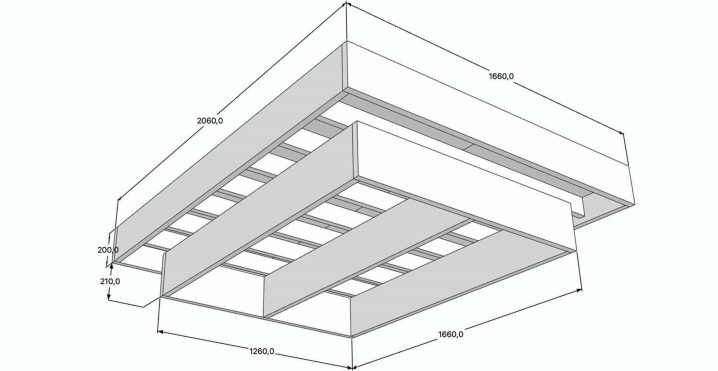

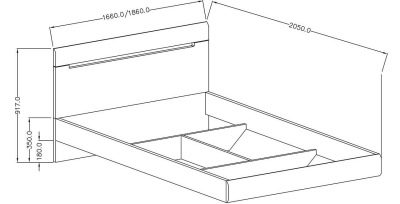

Schemes and construction drawings

Floating beds are generally arranged in the same way as ordinary beds: this is the frame where the mattress is placed and its support. There are several types of bases.

- "Secret" legs... Such beds have legs, but they are not located in the corners, but in depth on the supporting beams of the bed.

- Reduced box. The bed rests on a square or rectangular base, which is smaller than the frame.

- "Underframe". By analogy with single-legged tables, the bed is supported by just one small support. At the same time, in order to avoid overturning, such models are bolted to both the floor and the wall.

- Hinged... The L-shaped profile of the required height is mounted vertically, and on its basis the bed itself is already assembled. A beautiful headboard will help to hide the attachment points. In an effort to achieve a unique design, some even hang the bed from the ceiling with chains. So the structure will sway slightly when moving, which adds an additional flavor to the design of the bedroom.

- Transparent base. A box is made of high-strength glass, on which the mattress is laid. The most controversial option in terms of care, cleaning and maintenance. But the appearance is simply amazing.

The choice of the base depends on the final size of the berth. For double spacious beds, it is better to choose a combined type: both to the floor and to the wall. Or a stable structure, not too narrow, so that the furniture does not overturn if you sit abruptly on the edge.

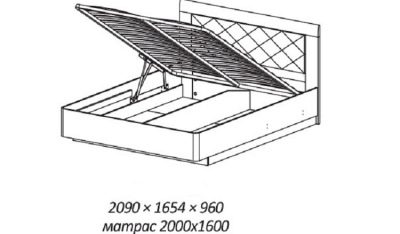

Usually boxes for linen are hidden inside the box on which the bed rests, but in our case the ultimate goal is to get rid of this element. If you need extra storage space inside the bed, consider lifting models.

Consider the desired height when constructing the drawing. The larger it is, the narrower and more imperceptible the support should be.

Also, the scheme should take into account the places of the greatest load. These are the edges of the bed where people sit before lying down and the middle where they sleep. The attachment points must be strong, and the fittings must be of high quality. You can entrust this stage to professionals who can calculate the load on each structural element.

How to make a frame out of wood?

Wood is a durable and popular environmentally friendly material for furniture production. It is easy to work with it if you decide to make a bed with your own hands, and the final weight of the structure will be less than that of a metal one. Take all measurements in advance to buy the required amount of material. To save money, external elements can be made of chipboard or MDF.

Tools and materials

To make a bed made of wood, we need:

- boards of different lengths for the frame;

- plywood for the base of the bed;

- strong bars to strengthen the structure;

- drill for mounting holes;

- jigsaw for cutting elements of the desired size;

- screwdriver;

- building level;

- screwdriwer set;

- roulette;

- various self-tapping screws, furniture plugs and other accessories;

- iron corners for fastening;

- LED strip, if backlighting is planned;

- facing materials - fabric, foam rubber, chipboard, MDF, depending on the design project.

Manufacturing steps

It is better to assemble a bulky structure at the installation site. Prepare your bedroom by removing the excess and covering the furnishings with dust foil.

- The bed is collected from the bottom up. First, we create the base box. There should be several crossbars inside it for strength. Place them at a distance of 30-40 centimeters from each other, depending on the size. This type of construction implies that the edges of the frame will not extend beyond the base by more than 30 cm. For additional stability, the side that will adjoin the wall may not have an indent.

- Then collect the bed. Beams from a bar are attached to the frame. They should be aligned with the crossbars of the base, so the bed will be stronger. The lower part, which will "float", is equipped with beams running across, with the same distance between.

- Both elements are connected using pillars from the floor to the edge of the bed. These pillars are mounted at the junction of the crossbars.

- Cover the wood with varnish or paint to protect it from moisture and vermin... At this stage, a backlight is attached, if needed.

- It remains to cover the bed with plywood and fasten the sides. Their height is determined by the parameters of the mattress. The sides can be made not from wood, but from other materials.

- The headboard is prepared separately and attached to the finished structure. At your request, it can be just a decorative chipboard sheet or OSB board, covered with a fabric with a foam rubber filler.

Making a bed from metal

It is more difficult to make a metal structure at home - the work requires certain skills and experience.

If you are not completely sure of yourself, entrust the production of parts to professionals according to your drawings, and at home just assemble the "designer". These beds will last for many years.

Despite its heavy weight, metal is much stronger than wood and can withstand high loads.

To work you will need:

- tape measure and marker for marking;

- grinder with a set of cutting and grinding wheels for metal;

- drill with special drills;

- clamps, clamps, clamps;

- square metal profile;

- plywood for the bed;

- facing materials for sides and headboards;

- fittings for fastening.

You can use welding instead of bolts. Do not forget about protective equipment when working with the welding machine.

Assembling a metal frame is not very different from the stages of working with wood.

- Assemble the bed frame from the profile tube. Add crossbeams to reinforce the structure, but don't overdo it to keep the final weight off the scale.

- Place the feet at the intersection of the crossbars.It is best to place them at a distance of 30-40 centimeters from the edge.

- Sand the structure and varnish to protect it from moisture and corrosion.

- Install the bumpers and platform under the mattress, headboard.

Useful Tips

- When choosing a bed height, be guided by your own comfort. To select a support that will not be visible from the side, move away from the installation site as far as possible. This will give you an idea of what type of attachment is right for you, given that the legs should not be deeper than 40 centimeters under the bed.

- You can just walk through furniture showrooms and see samplesto find out which model will suit you best.

- To enhance the floating effect, match the color of the box and base to the shade of the floor... Visually, such a step will help to fit the object into the interior.

- If you would like to opt for the option with a mount without legs, study the wall material. The high headboard will further strengthen the structure.

- When estimating the size of the future bed, start from the parameters of the mattress that you plan to use. In the production of furniture, firms take into account the standard sizes of sleeping places, so it is easy to choose filling for any bed purchased in a store. Don't forget this when planning your custom furniture.

- When assembling the base, protect the legs with furniture pads so that they do not leave marks on the floor. This is especially true for metal structures.

How to make a floating bed, see below.