How to make a mattress with your own hands?

Making a mattress with your own hands is a feasible task, so do not rush to the store for a new one when the old mattress is out of order. In the article we will talk about how to make it at home from foam rubber, how to make it using pillows and other materials at hand.

Made from foam rubber

Foam rubber is a traditional filler for upholstered furniture and mattresses.

Before you decide to make a product yourself at home, decide on the degree of rigidity of the future bed base. Based on your preferences, choose the appropriate type of foam rubber.

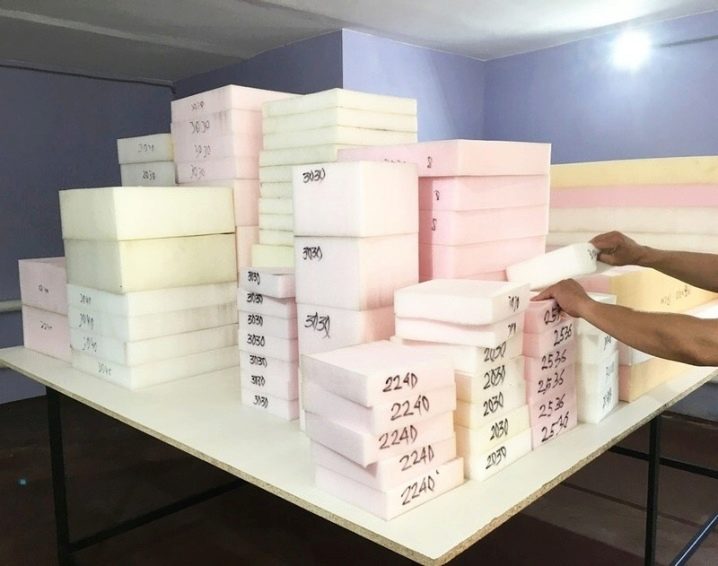

It will be difficult for a beginner to figure out the density of polyurethane foam on his own, however, in each specialized store, consultants are always ready to help. However, the density is indicated on the labeling of the goods, it remains only to figure out the designations.

-

HS is a soft foam rubber; it is not used separately for stuffing, but is used only as a top layer.

-

ST - the standard version, more suitable for mattresses for children and teenagers. Such a filler can last for a maximum of 5 years.

-

EL - a brand with a density of up to 30 kg per cubic meter is intended for covering a mattress on which a person weighing up to 100 kg will sleep.

-

HL - foam rubber with such markings and a density of over 40 kg per cubic meter allows you to make a mattress with your own hands without springs. It will withstand people weighing more than 100 kg, but it can be uncomfortable for thin people. Will last 10 years or more.

-

HR - suitable for recreation of people of all weight categories. Differs in high elasticity and wear resistance: the minimum service life is 15 years.

-

VE - this brand of foam rubber is considered innovative. The material is able to remember the shape of the body, but not everyone is recommended to sleep on anatomical mattresses. Before sheathe your mattress with such foam rubber, it is better to try to lie on a similar product and understand whether it is convenient for you.

In addition to Latin letters, there are 4 numbers in the foam rubber marking: the first two denote density and the next two denote stiffness.

Preparation

After choosing a filler for the frame (it is better to take foam rubber with increased rigidity: EL, HL), prepare the following tools that you will need in your work:

-

a length meter (it is more convenient to use a tape measure) and something to indicate marks (a marker is suitable);

-

a sharp object for cutting foam rubber (it is convenient to do this with a clerical knife, a breadboard knife is also suitable);

-

special glue;

-

zipper and textiles for sewing the cover (it is better to take a zipper lock and use a dense fabric - jacquard is also suitable);

-

sewing accessories (threads, scissors, sewing machine needles and the sewing machine itself).

Measurements are taken from the inside of the frame. Around the perimeter of the base of the mattress, rigid polyurethane foam with a thickness of up to 5 cm is used.

Execution technology

The assembly of the product takes place according to a simple principle.

-

The base for the frame is cut out, the strips are glued together, and a rectangular contour is formed.

-

Further, along the perimeter, they begin to fill with foam rubber. With a multilayer version, the main thing is to lay a solid sheet from below, the remaining layers can be formed from pieces.

-

The frame is filled to the top (the top layer, if desired, is laid with soft foam rubber - not less than 5 cm).

-

All parts are glued together and with the frame shell with special glue.

At the finish, the product must be dried, as indicated in the instructions for use of the adhesive.

Cover sewing

For a mattress, choose a cover made of quilted or upholstery fabrics or just thick textiles. You can also use a material with a thin padding polyester layer or with batting. Only in this case, when sewing, select the appropriate sewing machine needles so as not to damage the sewing equipment.

The cover is cut out according to the dimensions of the frame: the length, width, and height of the foam filler are measured. Allowances are left only for the seams, since the cover should fit snugly around the padding, without folds.

To create a more stable position of the filler in the "clothes", a ribbon tape is passed at the seams.

Thus, the seams are not stretched during the operation of the product, and the mattress is not deformed. If the cover is sewn as a non-removable element, after pulling it on, the open area is sewn up with blind stitches. The cover is needed primarily for tightening the glued foam rubber, as well as for hygiene.

It is better to put on a non-removable cover with an assistant. A removable mattress cover is sewn in the same way, only it comes with a zipper that is sewn in from either side. For the fastener, choose a long zipper, the longer it is, the faster you can cope with filling the case.

It is best to place the fastener on two sides, with the capture of the corner part of the mattress topper or two corner parts at once. That is, place it from the middle of one side to the middle of the other side of the cover. With such a wide space, the foam mattress will easily enter there.

How to make pillows?

A mattress can be made from pillows - this product is more suitable for children. Depending on what size is needed, the cover is sewn first. To do this, you need pillowcases that are sewn to each other. Then such a mattress topper is stuffed with pillows or foam rubber of appropriate hardness.

You can also use a synthetic winterizer as a filler (take at least 200 g per 1 square meter based on density) - only in this case they will have to "fill" the mattress well. On such a product you can lie, play on the floor for children.

If it is not very comfortable to sleep on such a mattress, then it will definitely protect you from the cold. To make a mattress from pillows, you can use ready-made pillows. If there are no extra ones available, you will first have to start sewing pillows, and then make a mattress out of them.

You need to sew naperniki (usually 5 pillows 50x30 cm are enough for a children's mattress), fill them with padding polyester, sew up the open side (you can sew on a sewing machine, or you can manually sew a blind seam). Then you need to start sewing a mattress cover of the appropriate size.

You can take 2 cuts of fabric (assuming that the mattress will turn out to be 1.5x0.5 meters), fold the wrong sides and sew them together. Leave 2 centimeters for the seam allowance. After stitching three edges, the cover is turned onto the front side.

One by one, the pillows are pushed in, separating them with a seam: that is, there is a line between them. The result should be an accordion mattress. The open side is sewn up. But you can make a kind of pockets for each pillow. In this case, they will need to be zipped, or buttons sewn on the side. This cover is washable.

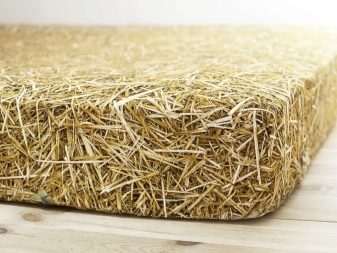

Homemade mattress made from natural materials

There are many workshops on how to make a mattress from available tools. Straw, hay, sheep's wool and other materials can be used. Straw and hay bases will require covers with a high density - this is important, since nothing should interfere with rest, and dried grass or rough straws can make their way through a thin mattress topper.

I must say that our ancestors mostly slept on such products. It is necessary to dry the straw and grass well, select coarse particles and fill the mattress topper.

By the way, such options are perfect for outdoor recreation and for those who like to sleep outside in the country during the warm season.

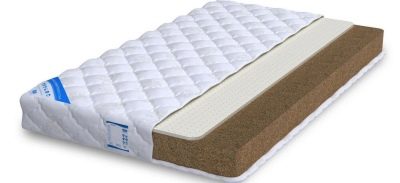

We create an orthopedic model

You can make an orthopedic product in the form of a mattress using a spring block. Usually, the mechanism is chosen smaller than the case, so that it is about 3-4 cm smaller around the perimeter. First, two solid plates (bottom and top) are assembled, the sides are attached and a spring block is fixed in the middle (or several, if one of a suitable size could not be found).

2 layers of batting are placed on the spring (can be replaced with felt), and then foam rubber is placed.

Two protective layers are needed in order not to damage the main filler. By the way, you need to put it on glue, dry it, and only then cover the finished product with textiles.

The fabric for the cover of the orthopedic model is usually chosen more densely. Such a product is often made without springs.

-

It is not so easy to buy spring blocks separately,

-

In the opinion of many, springiness does not give the mattress more preventive properties.

The rigidity, which is beneficial for the spine, in a springless product is created by alternately stacking polyurethane foam and coconut fiber. And in order to regulate the level of rigidity, foam rubber is placed on top of the mattress, and coconut coir is placed below.

Depending on the need, the mattress is turned over as needed. For the manufacture of children's products, use only natural, non-toxic and anti-allergenic materials. However, the same rules apply to adults: it is not recommended to save on your own health, especially when it comes to a preventive device.

How to make a mattress with your own hands, see below.